Introduction

The Industrial Internet of Things (IIoT) is transforming modern manufacturing. Factories are increasingly adopting connected devices, sensors, and automated systems to optimize operations, reduce downtime, and improve efficiency. At the heart of this transformation is reliable connectivity, enabling machines to communicate, collect data, and respond in real time.

For industrial operations, standard internet connections or Wi-Fi networks often cannot meet the scale, reliability, and security requirements of modern factories. IoT SIM cards provide a dedicated, secure, and flexible connectivity solution tailored for industrial equipment monitoring.

At Zhongyi IoT, we specialize in providing high-quality IoT SIM solutions designed specifically for factories, allowing seamless remote monitoring of machinery, sensors, and production lines. In this article, we explore the role of IoT SIM cards in factory equipment monitoring, their types, benefits, applications, and how choosing the right provider can drive operational excellence.

1. Understanding IoT SIM Cards

An IoT SIM card is a specialized SIM card designed to connect Internet of Things devices to cellular networks. Unlike traditional SIM cards for phones, IoT SIMs are optimized for:

- Long-term deployments – many industrial devices operate continuously for years without human intervention.

- Low power consumption – essential for battery-powered sensors or devices in remote areas.

- Reliable connectivity – ensures data is transmitted consistently, even in harsh industrial environments.

- Remote management – allows operators to monitor, activate, or suspend devices without being physically present.

IoT SIM cards are the communication backbone of factory monitoring systems, enabling machines, sensors, and control units to transmit data to central platforms or cloud systems for analysis.

2. Why Factory Equipment Needs IoT Connectivity

Modern factories rely heavily on data-driven insights. Without continuous connectivity, critical equipment monitoring and predictive maintenance efforts would be ineffective.

2.1 Real-Time Equipment Monitoring

IoT SIM-enabled sensors and devices allow factories to track machine health parameters such as temperature, vibration, energy consumption, and operational status. Real-time data helps identify anomalies early, preventing unexpected breakdowns and costly downtime.

2.2 Predictive Maintenance

Instead of following a fixed maintenance schedule, industrial IoT devices can predict failures by analyzing trends in sensor data. IoT SIM cards ensure that this data is reliably transmitted to maintenance platforms in real time, enabling proactive intervention.

2.3 Remote and Multi-Site Management

Many factories operate multiple production sites. IoT SIM cards enable centralized monitoring, allowing operations teams to manage machines and equipment across different locations from a single platform.

2.4 Global Deployment

For multinational manufacturers, IoT SIM cards provide cross-country connectivity, ensuring that equipment in various regions remains online without the need for local SIM swaps.

2.5 Security and Compliance

Industrial data is sensitive. IoT SIM cards provide encrypted communication channels, device authentication, and compliance with global security standards, protecting operational data from cyber threats.

3. Types of IoT SIM Cards for Industrial Applications

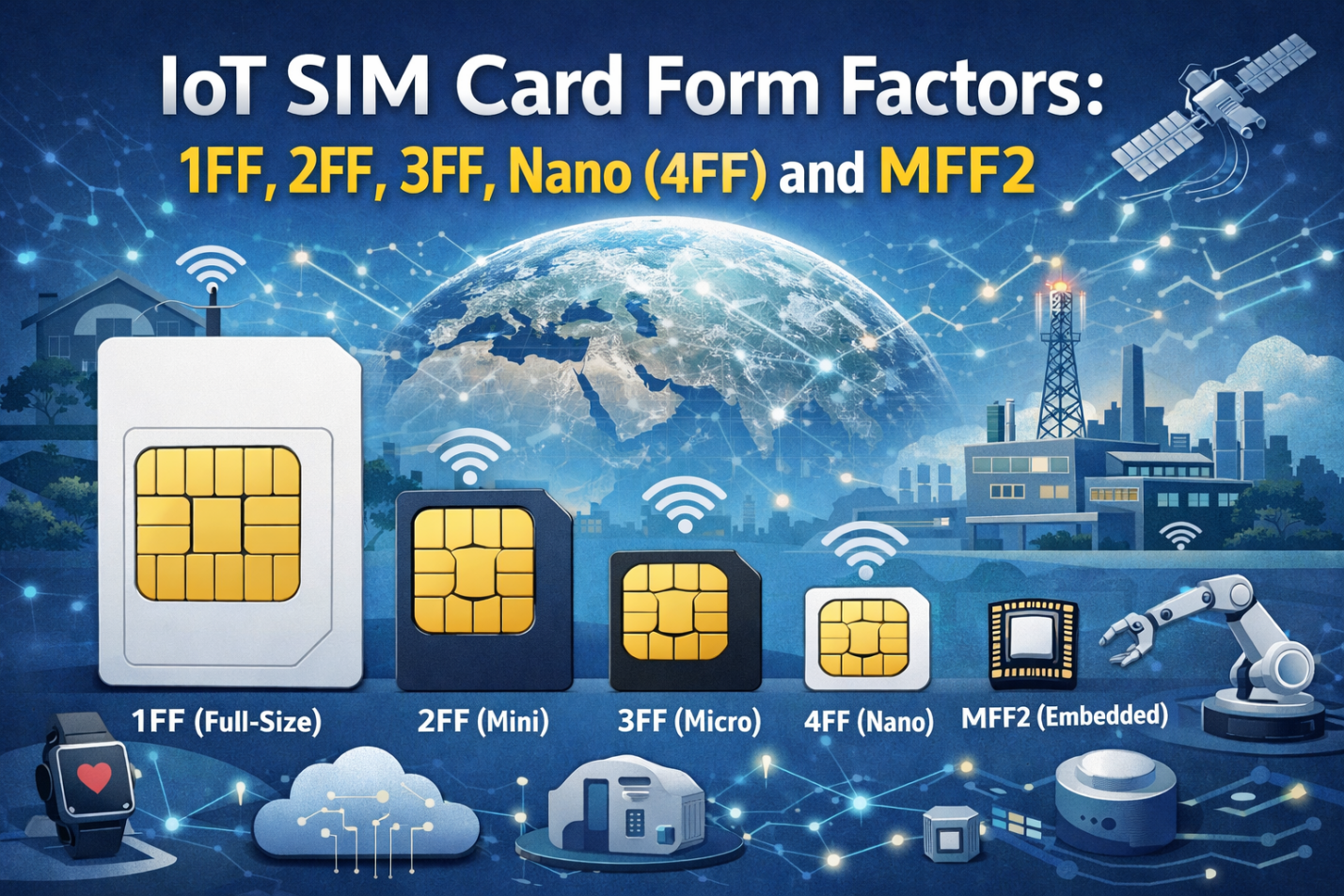

Different factory equipment has different connectivity needs. Zhongyi IoT provides multiple types of IoT SIM cards to suit various scenarios:

3.1 M2M SIM Cards

- Designed for machine-to-machine (M2M) communication.

- Ideal for industrial sensors, PLCs (Programmable Logic Controllers), and automated production systems.

- Offer durability in harsh factory environments, with resistance to temperature extremes and vibration.

3.2 eSIM for Industrial Devices

- Embedded SIM (eSIM) allows remote provisioning without physical replacement.

- Supports multiple network profiles, enabling network redundancy.

- Useful for machines deployed in hard-to-reach locations.

3.3 NB-IoT SIM Cards

- Narrowband IoT SIMs are low-power, wide-area network solutions.

- Perfect for sensor networks and equipment with low data requirements but high reliability needs.

- Extend battery life for devices such as environmental sensors, smart meters, or energy monitors.

3.4 CAT M1 SIM Cards

- Provide higher bandwidth and lower latency than NB-IoT.

- Suitable for machines that require frequent data transmission or real-time remote control.

- Commonly used in industrial automation, robotics, and fleet management.

4. Benefits of Using IoT SIM Cards for Factory Equipment Monitoring

IoT SIM cards offer a wide range of benefits that directly improve factory operations:

4.1 Continuous Device Connectivity

- IoT SIM cards ensure that machines stay connected even in areas without Wi-Fi.

- Critical for factories with large facilities, underground machinery, or distributed equipment across sites.

4.2 Cost Efficiency

- Optimized data plans reduce operational costs compared to mobile SIM cards or dedicated leased lines.

- Bulk data packages and long-term IoT SIM subscriptions are cost-effective for industrial deployments.

4.3 Enhanced Security

- IoT SIM cards support encrypted data transmission and secure device authentication.

- Industrial operations are protected from potential cyber threats, ensuring data integrity.

4.4 Remote Management

- Operators can monitor equipment, activate or deactivate devices, and manage SIM profiles remotely.

- Reduces the need for on-site personnel, saving time and labor costs.

4.5 Scalability

- IoT SIM cards allow factories to scale monitoring solutions easily.

- Whether deploying tens, hundreds, or thousands of devices, SIM cards can be provisioned remotely and managed centrally.

5. Applications of IoT SIM Cards in Factory Equipment Monitoring

5.1 Industrial Automation

- Monitoring assembly lines, robotics, and CNC machines.

- Tracking machine performance to optimize production efficiency.

5.2 Energy and Utility Monitoring

- Sensors monitor energy consumption, temperature, and operational efficiency.

- IoT SIM cards transmit data in real time to energy management platforms.

5.3 Predictive Maintenance

- Vibration, temperature, and operational sensors detect early signs of wear.

- IoT SIMs enable continuous data flow for predictive maintenance algorithms.

5.4 Warehouse Management

- Inventory and conveyor systems can be monitored remotely.

- IoT SIMs provide connectivity for mobile scanners and automated storage/retrieval systems.

5.5 Environmental Monitoring

- Factories can monitor temperature, humidity, or emissions to comply with safety regulations.

- Low-power NB-IoT SIMs transmit sensor data efficiently.

6. Choosing the Right IoT SIM Provider

Selecting the right provider is critical to ensure reliability and efficiency in factory monitoring. Key factors include:

6.1 Network Coverage

- The provider should offer local and global coverage for multi-site factories.

- Zhongyi IoT supports multi-network connectivity to guarantee uptime.

6.2 Data Plans and Flexibility

- Flexible IoT SIM plans based on data consumption and device type help control costs.

6.3 Security and Compliance

- End-to-end encryption, device authentication, and compliance with ISO or IEC standards.

6.4 Management Platform

- A user-friendly SIM management platform enables real-time monitoring, activation, and troubleshooting.

6.5 Customer Support

- 24/7 technical support ensures rapid response to connectivity issues.

7. Why Zhongyi IoT Is the Ideal Choice

At Zhongyi IoT, we provide comprehensive IoT SIM solutions for industrial equipment monitoring:

- Global Coverage – connect machines anywhere in the world.

- Multiple SIM Types – MFF2, CAT M1, NB-IoT, eSIM for all factory needs.

- Customizable Plans – unlimited or tailored data plans for efficiency and cost control.

- Advanced Management Platform – monitor, activate, or suspend devices remotely.

- Security and Reliability – end-to-end encryption and network redundancy ensure uptime.

By using Zhongyi IoT SIM cards, factories can achieve real-time equipment monitoring, predictive maintenance, and scalable automation, resulting in improved productivity, cost savings, and operational intelligence.

8. Future Trends in Industrial IoT Connectivity

8.1 5G IoT SIM Cards

- Ultra-low latency and high bandwidth enable autonomous machines, robotics, and AI-powered factories.

8.2 eSIM Adoption

- Simplifies provisioning and allows devices to switch networks seamlessly.

8.3 AI Integration

- Data collected via IoT SIMs is analyzed using AI for predictive analytics and operational optimization.

8.4 Energy-Efficient IoT Devices

- NB-IoT and LTE-M SIMs reduce energy consumption, supporting sustainable industrial operations.

9. Conclusion

Monitoring factory equipment effectively is no longer optional—it is essential for maintaining competitive advantage in modern manufacturing. IoT SIM cards provide the reliable, secure, and scalable connectivity required to enable real-time monitoring, predictive maintenance, and remote management.

With Zhongyi IoT, factories gain access to high-quality IoT SIM solutions that ensure:

- Continuous connectivity across local and global sites

- Enhanced security and data protection

- Scalable deployment for hundreds or thousands of devices

- Efficient management and cost-effective plans